Your luxury handbag's value depends on its authenticity. But what if fakes become identical? I saw Burberry's bags face this threat and will show you how they survived.

Burberry saved its handbags by pulling production from compromised factories. This strategic retreat under Daniel Lee regained control over core manufacturing secrets—from leather sourcing to hardware specs—making their new bags secure and once again distinguishable from counterfeits.

As a buyer specializing in high-end leather goods for over 18 years, my reputation is built on guaranteeing authenticity. A few years ago, that guarantee became impossible with Burberry bags. The fakes became perfect—not just good, but flawless. This wasn't just a reseller's problem; it was a crisis threatening to permanently devalue every genuine Burberry bag in existence. I'm going to explain how their handbag supply chain was breached and the drastic steps they took to protect their most valuable products.

Why Did Even Experts Fail to Spot Fake Burberry Bags?

Your expertise is your advantage. But what happens when you're staring at two identical Burberry bags and can't tell the multi-thousand-dollar original from the fake?

Experts failed because counterfeiters replicated every minute detail of the bags, from the specific grain of the leather to the weight of the hardware. The fakes were so perfect that official authenticators refused to make a final call, killing market confidence.

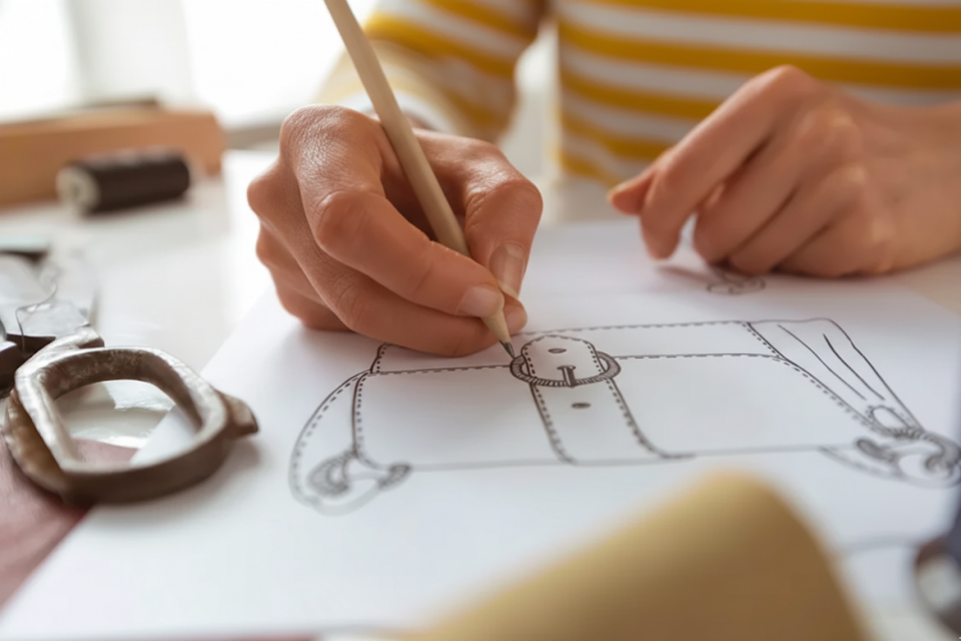

Side-by-side comparison of a real vs. fake luxury bag clasp](https://web.chinahandbagmanufacturer.com/wp-content/uploads/2025/10/Burberry-it-bag.png)

I have to be honest: this crisis almost broke my professional confidence. I remember having two Burberry TB bags in front of me—one real, one fake—and I couldn't find a single flaw to make a definitive call. The grain on the lambskin was identical. The chain strap had the same weight and acoustic signature when I dropped it on the table. The stitching count per inch around the flap was perfect. I sent a few high-risk bags to top-tier authentication services, and they were returned with an "inconclusive" verdict. When the people who do this for a living can't be sure, the game is over. I had to make a painful business decision: I stopped acquiring and authenticating all popular Burberry bag styles from that era. The financial and reputational risk was simply too high.

How Did a Handbag Supply Chain Leak Cause This?

You trust your manufacturing partners with your designs. Burberry did, too. That misplaced trust led to their core handbag secrets being sold to counterfeiters.

The crisis was caused by leaks from Burberry's own factories. Contractors were given digital patterns, hardware molds, and even NFC chip data, allowing counterfeiters to build bags with the exact same materials and technology as the authentic ones.

As someone who manages production, I knew these perfect fakes were not the work of reverse engineering. They were built from original blueprints. Burberry, in its pursuit of lower costs, had outsourced production to factories that lacked sufficient security. They handed over everything. We're not just talking about a sketch of a bag. We're talking about the digital CAD files for cutting the leather panels perfectly, the exact alloy composition for the TB clasp, the supplier information for their custom Italian zippers, and even the programming for the NFC chips they started embedding in linings for authentication. This was a catastrophic failure in supply chain management.

| Leaked Handbag Component |

Impact on Counterfeits |

| Leather & Canvas Codes |

Fakes were made with identical, officially sourced materials. |

| NFC Chip Data |

Replicated chips passed authentication scans on smartphones. |

| Hardware Molds |

TB clasps and zippers were physically identical in weight and finish. |

| Digital Stitching Patterns |

Machine-sewn patterns were flawless, with no human error. |

This wasn't imitation; it was unauthorized production. The counterfeiters weren't just making a "Burberry bag"; they were making the Burberry bag, just outside the official system.

How Did Daniel Lee's Strategy Fix the Handbag Crisis?

Your brand's core product is compromised. Do you tweak the design, or do you burn down the factory and start over? Burberry chose the latter.

Daniel Lee fixed the crisis by pulling handbag production out of all compromised facilities. This strategic overhaul cut off the supply of technical data to counterfeiters, immediately making his new bag collections secure and harder to fake.

When Daniel Lee took over, the industry was watching for his first big "it" bag. But his most brilliant move had nothing to do with design; it was a strategic masterstroke in manufacturing. He initiated a radical overhaul of the handbag supply chain, effectively abandoning the network of domestic factories that had been leaking information. This was a hugely expensive and disruptive decision, but it was the only way to stop the bleeding. By bringing production back to a smaller circle of highly secure, trusted workshops, Burberry severed the connection between their engineers and the counterfeit market. The flow of secrets stopped overnight.

The effect was clear. The bags from his new collections are once again defensible. The fakes you see now have clear tells—the hardware is off, the leather quality isn't right. My confidence in sourcing and authenticating new-season Burberry bags is back. It was a brutal, costly, but ultimately successful campaign to reclaim the integrity of their most iconic products.

Conclusion

Burberry's handbag crisis is a critical lesson: protecting your product's integrity means having absolute, uncompromising control over your manufacturing secrets. Never outsource the keys to your bestsellers.

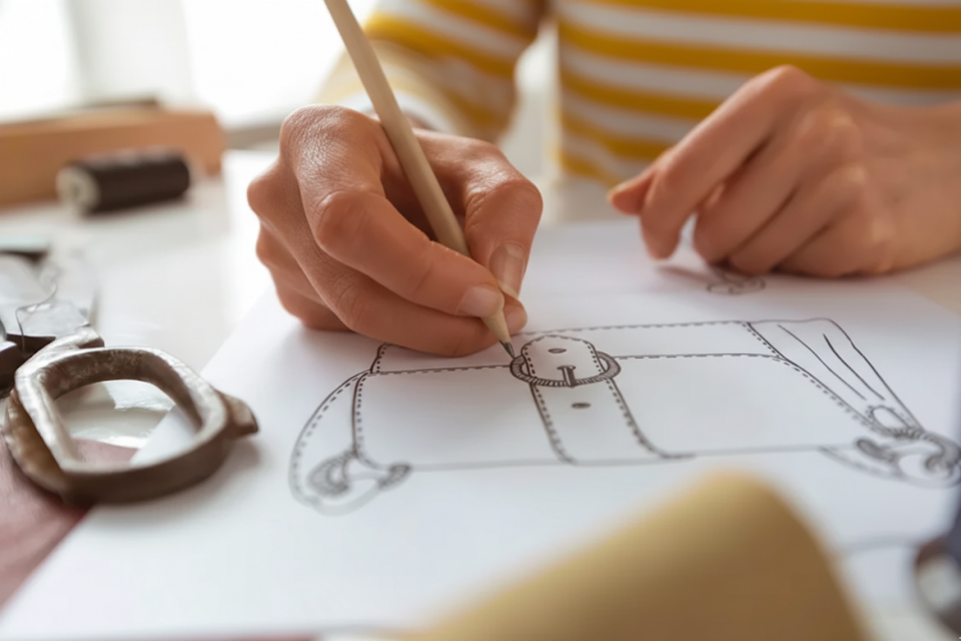

Side-by-side comparison of a real vs. fake luxury bag clasp](https://web.chinahandbagmanufacturer.com/wp-content/uploads/2025/10/Burberry-it-bag.png)